Pellicle Overview

- Definition & Usage

-

FST’s Pellicle Division develops and manufactures pellicles used in IC and FPD manufacturing processes.

A pellicle is a critical component that protects the photomask during exposure by preventing direct contact with contaminants or particles, thereby minimizing mask contamination and enhancing both yield and process reliability.

FST offers a comprehensive lineup of pellicles compatible with various exposure wavelengths.

Leveraging proprietary expertise in materials engineering, thin-film coating, frame bonding, and contamination control, FST provides fully customized solutions tailored to each customer’s process requirements.

- Purpose of Use

-

- Prevention of photomask contamination and physical damage

- Improvement of semiconductor device yield

- Extension of photomask cleaning cycles and overall service life

- Isolation from contaminants generated during repeated use

- Principle

- Structure

Principle

- Principle

- Structure

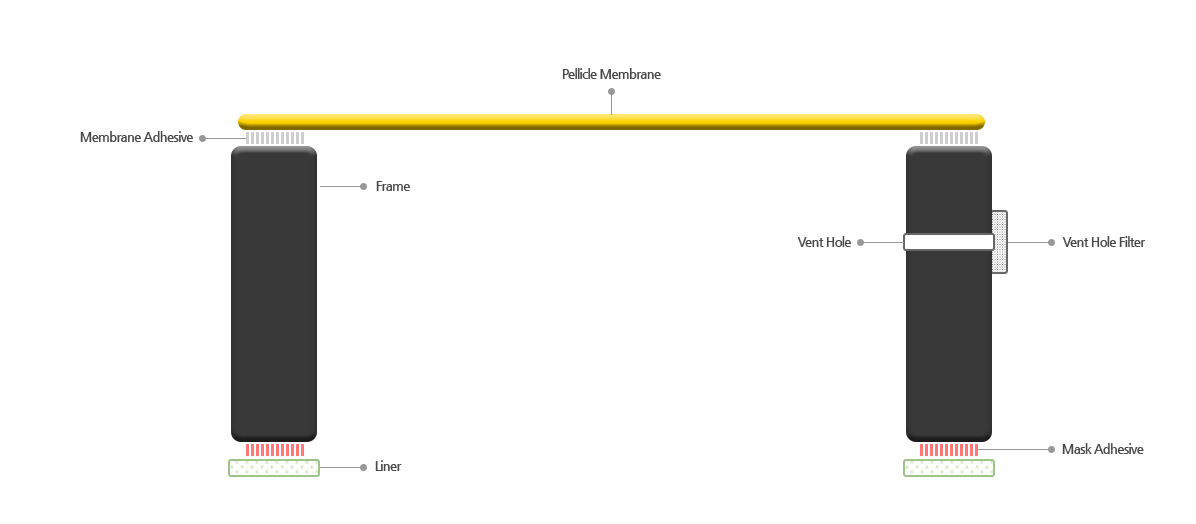

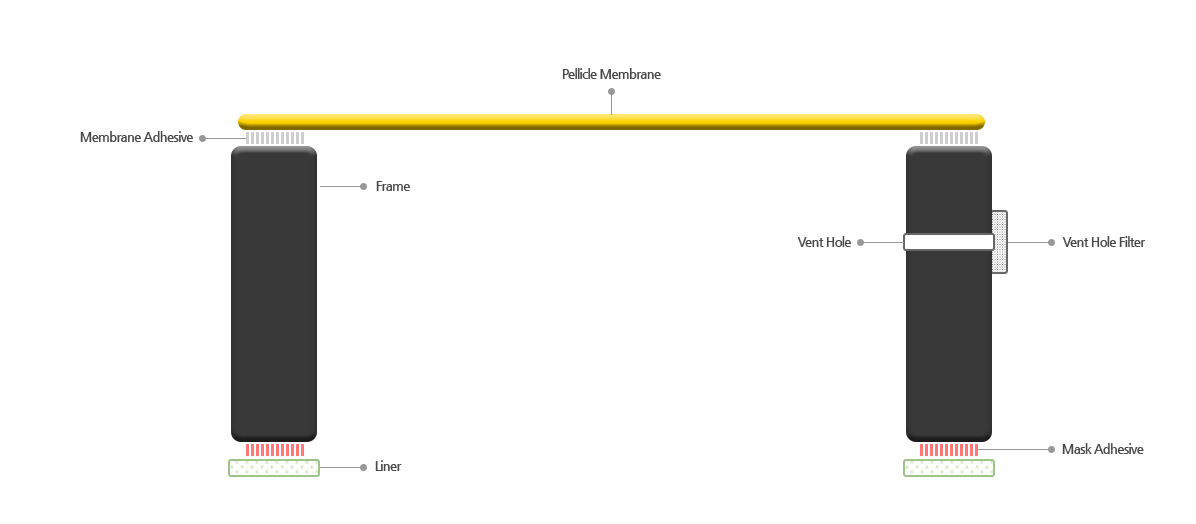

- Pellicle Structure

- Pellicle Membrane

A thin film optimized for each exposure wavelength, offering high transmittance, high mechanical strength, and excellent thermal stability. - Frame

A structural component that supports the membrane and mounts onto the photomask, designed for optimal thermal expansion characteristics and mechanical rigidity. - Membrane Adhesive

Bonds the membrane to the frame with high reliability, maintaining adhesion even under high-temperature and vacuum conditions. - Mask Adhesive

Applied in certain models to allow easy attachment and detachment from the photomask.

- Pellicle Membrane

Top