FST releases EUV infrastructure tools

페이지 정보

Witer 관리자 Comment 0 View 10,173 작성일 21-07-20 12:16본문

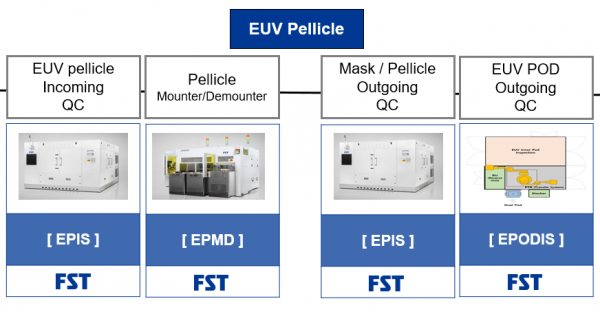

FST has been developing various EUV infrastructure tools and is ready to have new products commercially available

from the second half of 2021.

“FST has successfully developed the EPMDTM (EUV Pellicle Mounter/Demounter), a tool that automatically mounts (demounts)

EUV pellicles to (from) EUV masks, EPISTM (EUV Pellicle Inspection System) for EUV pellicle and mask inspection, and

EPODISTM (EUV Pod Inspection System) for EUV Pod inspection. The semiconductor equipment market has been dominated by overseas

companies. However, FST has succeeded in the localization of the tools mentioned above. These tools will contribute to the advancement of

EUV lithography infrastructure”, said Choi Sung-won, head of the FST R&D Team. With the technical know-how gained from the development of these tools, FST is developing EPAT (EUV Pellicle Assembly Tool) that can be utilized in the assembly of EUV pellicles.

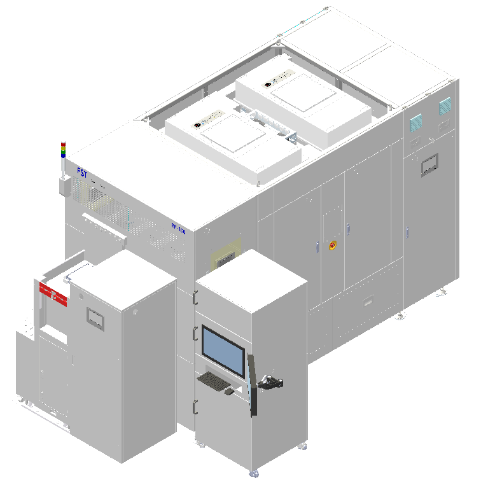

[EPMDTM] EUV Pellicle Mounter and Demounter

In 2019, FST began the development of EPMDTM, the fully automated EUV Pellicle Mounter/Demounter.

The build of a demo tool was completed in Q1 2021, and the evaluation with actual samples was completed in Q2,

resulting in the development of the world's first fully automated EUV Pellicle Mounter and Demounter.

FST is preparing to deliver this tool to major customers when the tool can be used in customers’ EUVL process.

The EPMDTM consists of three main units: Stud Fixation Unit (SFU), Mount-Demount Unit (MDU), and Stud Removal Unit (SRU),

all of which will be provided in an all-in-one automated system to the customers.

In addition, each unit can be operated

individually as needed, which can have different configurations according to customers’

preferences.

In February 2021, FST presented its

achievements in developing the EPMDTM at the SPIE Advanced Lithography Conference.

* The Society of Photo-Optical Instrumentation Engineers (SPIE) is an international non-profit organization for optical and photonics technologies established in 1955. The society operates technical conferences, trade exhibitions, and educational programs for researchers and developers in related fields. Also, it organizes conferences on next-generation lithography technology in February every year. In September, it organizes conferences with high concentration on photomasks and ultraviolet exposure technology.

[EPISTM] EUV Pellicle Inspection System

FST has completed the development of the EPIS-250, an EUV Pellicle inspection system, that can inspect EUV pellicle's membrane, frame, and

mask backside. A pellicle is a very thin film that physically prevents foreign substances from falling onto the mask pattern and is gradually

being adopted in the EUV exposure process.

The importance of EUV pellicle is increasing in semiconductor manufacturers that employ EUV exposure processes.

FST's EPIS-250 is mechanically designed to minimize damage to the fragile thin-film EUV pellicle.

Also, the system provides a variety of user-friendly features including an automatic review function to classify types and location of defects.

[EPODISTM] EUV POD Inspection System

FST has developed the EPODISTM (EUV Pod Inspection System) that can inspect EUV Dual Pods, a case that contains an EUV mask.

The EUV Dual Pod, a designated case for the EUV mask, consists of a pair of inner Pod and outer Pod. As the significance of contamination

control of the mask increases, FST developed the EUV Pod inspection system to help customers inspect defects on EUV Pods.

Top